Modular Belt Conveyors

Unitech manufactures a wide variety of slat and modular belt conveyors, which are designed to suit the exact requirements of the industry sector they are supplied to. This ranges from industrial warehousing to food, beverage and pharmaceutical environments.

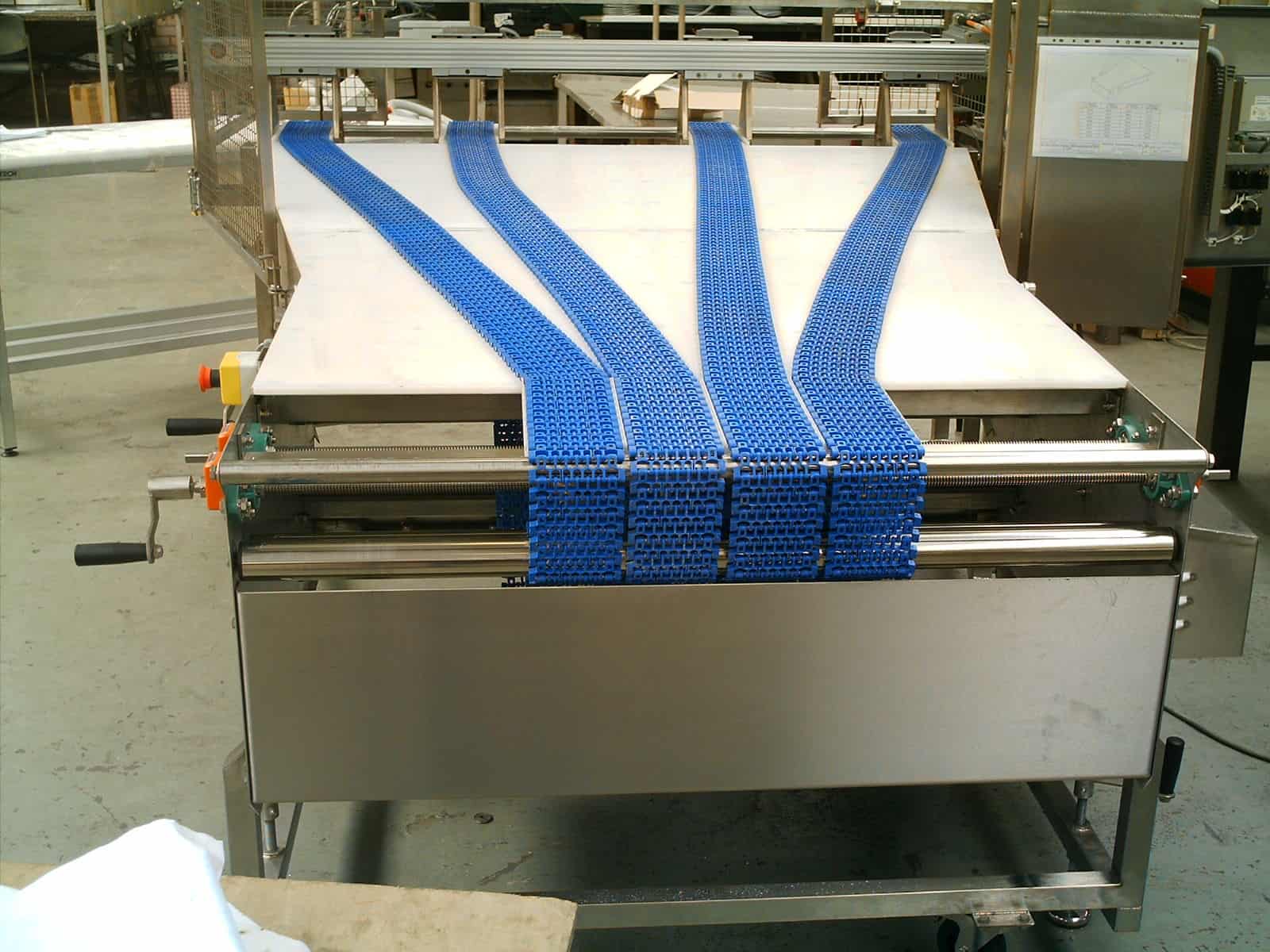

Our core modular belt conveyor design is primarily made of stainless steel. We utilise the latest modular belts and technology on the market to help facilitate the highest quality end product.

Product Features

- Manufactured from 304 and 316 stainless steel. Also available in mild steel, powder coated and aluminium.

- Options include full PLC-controlled systems or standalone units that can integrate with existing or new production lines.

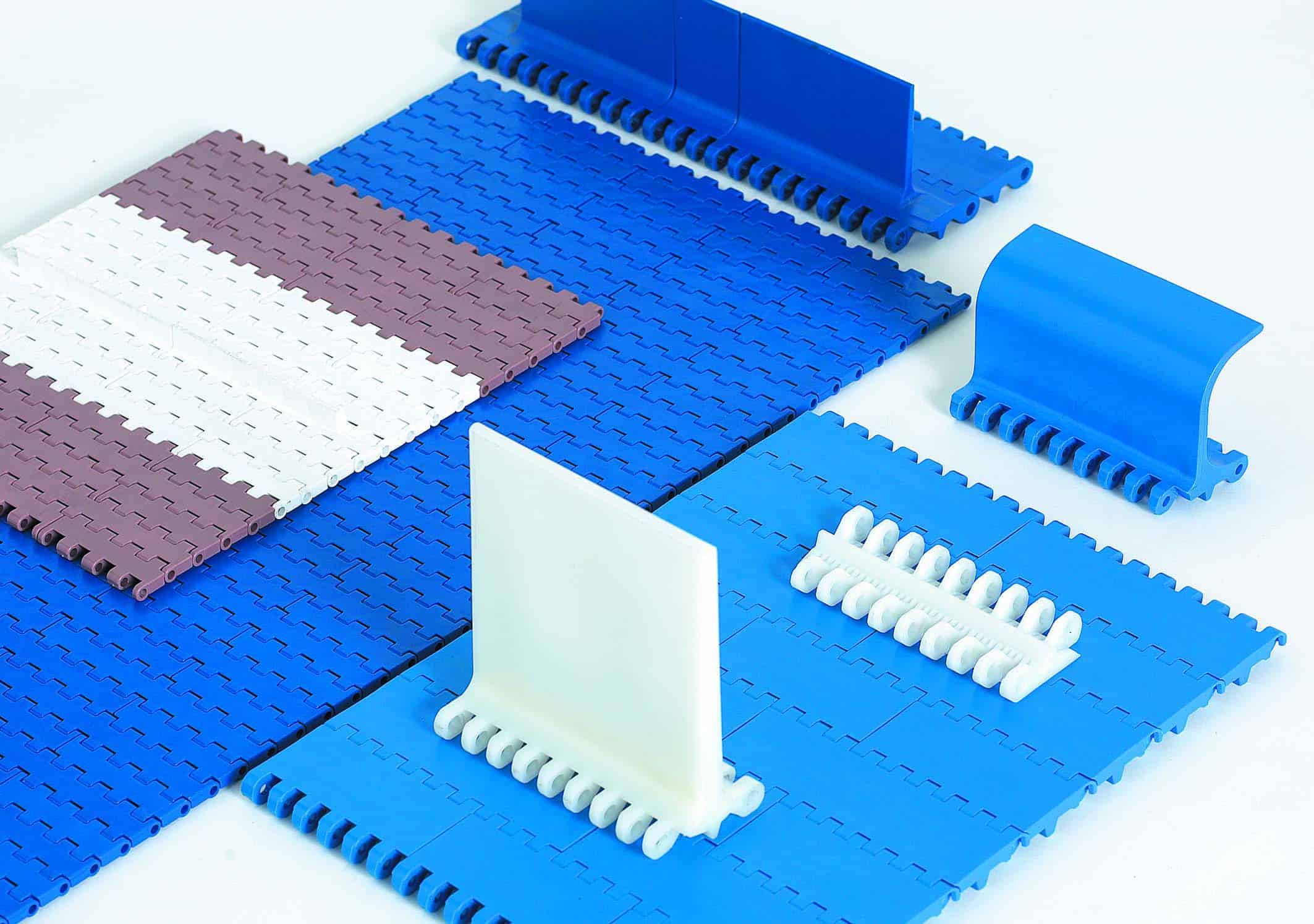

- Designed for easy cleaning and maintenance, compliant with latest EN BS & EHEDG guidelines.

- Vast array of conveyor widths available. Typically from (but not limited to) 85mm belt widths to 1500mm widths.

- Adjustable legs with standard adjustments of +/- 50mm and extended options of +/- 100mm.

Product Description

Our modular belt conveyors are extremely reliable systems, used to efficiently transport packed (or unpacked products) safely to their required destination. They can also be combined with depalletisation tables.

The belt’s flexibility allows us to design our modular belt conveyors for curved applications, ideal for areas where floor space is limited or where tight turns need to be navigated.

The construction of the belt makes it incredibly easy to maintain and clean – perfect for production lines handling raw products such as fish, meat or vegetables.

Our modular belt conveyors are great for the bakery industries where they are used as cooling lines for freshly baked goods. For example, a typical design would incorporate a spiral conveyor, allowing products to cool before returning to the line for packing.

Due to its high durability, the belt is able to withstand extreme temperature conditions, handling both hot and sharp products without any issue.

The belt is also suitable for flighted elevator conveyors where products need to be conveyed to differing levels.

Plastic Modular Belt Conveyor Design

Modular belt conveyors provide several benefits and as such, are a popular choice amongst many industries. This is due to the multi-functional properties of the modular belt and its high durability. And because the belt is constructed from interlocking plastic teeth (or modules), if anything did happen, replacing damaged or worn out parts is easy and quick.

Typical Configurations and Applications

- Accumulation conveyors and product buffer storage – to cover unpacked/packed products

- Bottling and canning applications

- Bakery application

- Combining conveyors and de-pal table applications

- De-watering systems

- Elevating applications – for both food and packed products

- Fish processing

- Integrated case packing and palletising systems

- Low back pressure (LBP) applications – to reduce pressure when accumulating

- Pivot/luffing belt conveyor configurations

- PLC controlled systems – for new lines, or integration into existing ones

- Poultry processing

- Product sortation and inspection systems

- Radius bend and tight radius conveyors

- Red Meat processing

- Salad and vegetable processing

- Spiral conveying applications – for both direct food contact and packed products

- Swan neck conveyors

- Tight radius belt conveyor design – for minimal footprint and floor space

The video above shows a modular belt conveyor being tested in readiness for installation into a large chicken processing company. This particular conveyor will be used as a chicken grading line and has white spacing lines to ensure chicken breasts are placed correctly to allow pieces to be graded by weight.

Get In Touch Today

Contact us today to get your modular belt conveyor project started

- Full turnkey conveyor solutions

- Over 70 years of experience

- In-house design team

- Friendly and helpful customer service

☎ – 01543 675800