Modular belt conveyors have become a popular choice for many UK businesses, so we thought it’s time to have a good look at what makes them special and why it may be worth the investment to help keep your production line moving, both safely and efficiently.

What is a Modular Belt Conveyor?

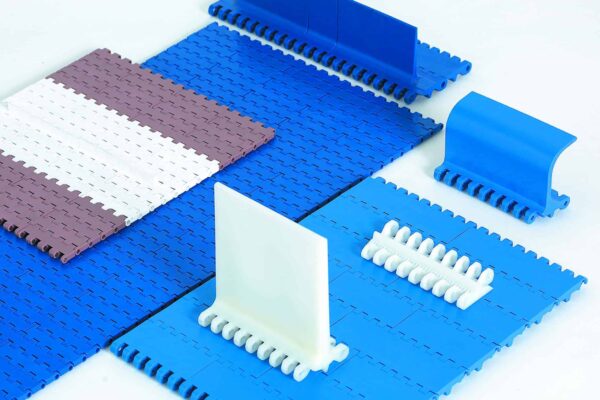

A modular belt conveyor system uses plastic links or ‘modules’ connected together to form a belt. These links snap together, (a bit like lego) to form a continuous surface that moves products along a production line.

This design makes them ideal for applications which require frequent cleaning, handling of sharp items, or navigating tight turns.

And because the belt is made from separate pieces, it’s easy to take apart and put back together. That simple feature is one of the biggest reasons companies choose modular belts.

What are the Key Benefits?

1. Easy to Clean, Easy to Maintain

Modular belts are often made from food-grade plastic and designed for quick disassembly, allowing for easy cleaning. The open-hinge design allows water and cleaning agents to reach all parts of the belt, ensuring thorough sanitation.

What’s more, if something breaks, you don’t have to replace the whole belt. Just pop out the damaged link and clip in a new one!

2. Built to Last

Modular belts are tough. The plastic materials used are designed to handle heavy loads and sharp items. They don’t tear or stretch like rubber belts can.

This strength means fewer stoppages and fewer breakdowns.

3. Handles More Than Just Straight Lines

We’ve been in the game for a long time, so trust us when we say that traditional belts don’t like corners. For modular belt conveyors however – it’s not a problem. They can be customised to fit various layouts, including curves, inclines, and declines.

4. Hot or Cold Products Can Be Transported

Modular belt conveyors work well in both hot and cold environments. The plastic modules can handle high temperatures, such as freshly baked goods, without warping. At the same time, they stay strong and reliable in frozen storage areas.

You don’t have to worry about belts cracking, melting, or wearing out too quickly.

Do They Cost More Than Standard Belts?

Yes, it’s likely a modular belt will be more expensive when compared to buying other belt types.

But for most businesses, the pros far outweigh the cons. And the money saved on repairs and downtime often covers that upfront cost pretty quickly. For example, you are far likely to experience fewer jams and less wasted energy starting and stopping machines.

What Industries Use Modular Belt Conveyor?

Modular belts are used in many industries across the UK and worldwide:

- Food processing

- Packaging lines

- Logistics

- Bottling plants

- Pharmaceuticals

- Recycling and waste management

And they’re only becoming more and more popular. According to a forecast report, the global modular conveyor belt market was valued at approximately USD 1.2 billion in 2023 and is projected to reach around USD 2.4 billion by 2032.

Interested? Talk to an Expert

We’ve been designing conveyor systems for years. We don’t just sell you a conveyor system, we help you find the right setup for your process. We look at your site, your products, and your goals. Then we build a modular conveyor system that works exactly the way you need it to.

Whether you need one conveyor or a full system, we’re ready to help. Simply contact us today on 01543 675800or drop us an email – info@unitech.uk.com