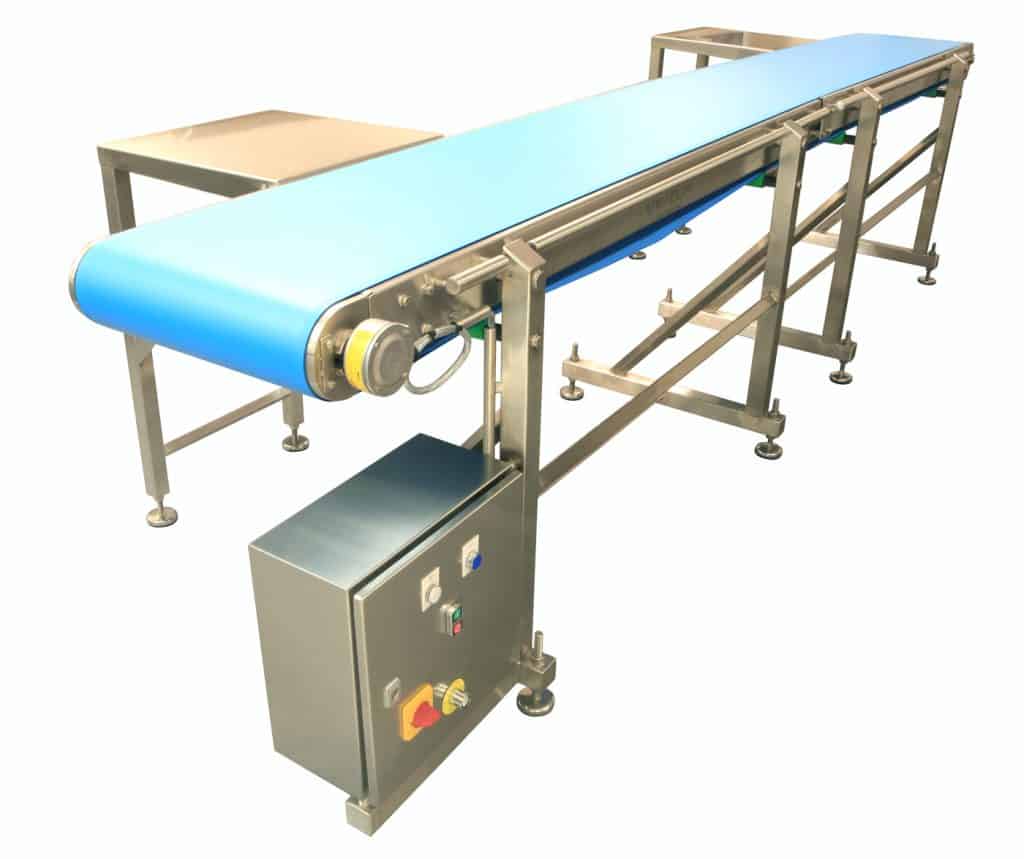

PU Belt Conveyors

Unitech offers high quality Polyurethane belts (or more commonly known as PU belts), designed for the transportation of products in packed or unpacked formats. They are a popular choice for the food sectors – in particular where raw, frozen and cooked food is used.

Product Features

- High resistance to wear and abrasion

- Cost effective

- Durable and robust design

- Fixed or variable speeds

- 304 and 316 stainless steel pressed side frame design – for light duty applications

- 304 and 316 stainless steel diamond box section construction – for heavier duty applications

- Cantilever design (full endless belt removal without the need for tools)

Product Description

Our polyurethane (PU) belt conveyors can be manufactured in a range of widths and lengths to suit your requirements. Additional fittings such as tracking guides and under trays can be easily fabricated should you require them. We design and develop our conveyor systems in the UK, utilising ultra hygienic designs which adhere to EN BS & EHEDG guidelines.

Our PU belt conveyors are constructed using stainless steel and are commonly supplied to the Fish, Poultry, Bakery and Salad industries.

In addition to our PU belt conveyors, we also build belt conveyors for pack and case products. These can easily be integrated into our automated packing conveyor systems. For more information, please contact us on 01543 675800 today.

High Performance Polyurethane Belts

The belt itself has a greater elastic memory than rubber counterparts, with excellent strength and durability. The material is extremely easy to clean and is resistant to oils, chemicals and other contaminants.

As no food usually resembles the colour blue, we mostly supply blue coloured PU belts for improved contrast.

Due to their hygienic and long lasting nature, our PU belt conveyors are perfect for the demanding needs of food production, or for any other process which deals with direct food to belt contact – all with a low cost of ownership!

They are supplied to a wide variety of applications. These include:

- Bakery applications

- Case and box handling systems

- Confectionary

- De-watering systems

- Fish processing

- Inspection systems

- PLC controlled systems (new or integrated)

- Poultry processing

- Meat processing

- Salad and vegetable processing

- Sortation systems

Typical Configurations

Our PU belts can be configured with the following conveyors:

- Horizontal conveyors

- Swan neck conveyors

- Elevating conveyors

- Bend conveyors

- Pivot conveyors

- Transfer conveyors

- Stay tracked belt conveyors

- Reciprocating conveyors (for freezer and oven loading)

Get In Touch Today

Contact us today to get your PU belt conveyor project started

- Full turnkey conveyor solutions

- Over 70 years of experience

- In-house design team

- Friendly and helpful customer service

☎ – 01543 675800