Conveyor Automation

Achieve Speed and Accuracy with Our Conveyor Automation Service

At Unitech, we can design and manufacture conveyor systems that go beyond just moving products. With expertise in conveyor automation, we help businesses streamline their warehouse operations.

No longer do you have to rely on manual processes. We add automation to conveyor belt lines for improved accuracy, consistency, and speed.

Why Choose Conveyor Automation?

With automation, your conveyor system can adapt to the needs of your business. Ideal for food production, manufacturing and packaging industries.

Reduce downtime and eliminate bottlenecks.

Automated systems run 24/7 for improved productivity.

Reduce reliance on manual labour and improve accuracy to save money in the long run.

Tailored solutions to meet your unique requirements.

What Equipment is Used?

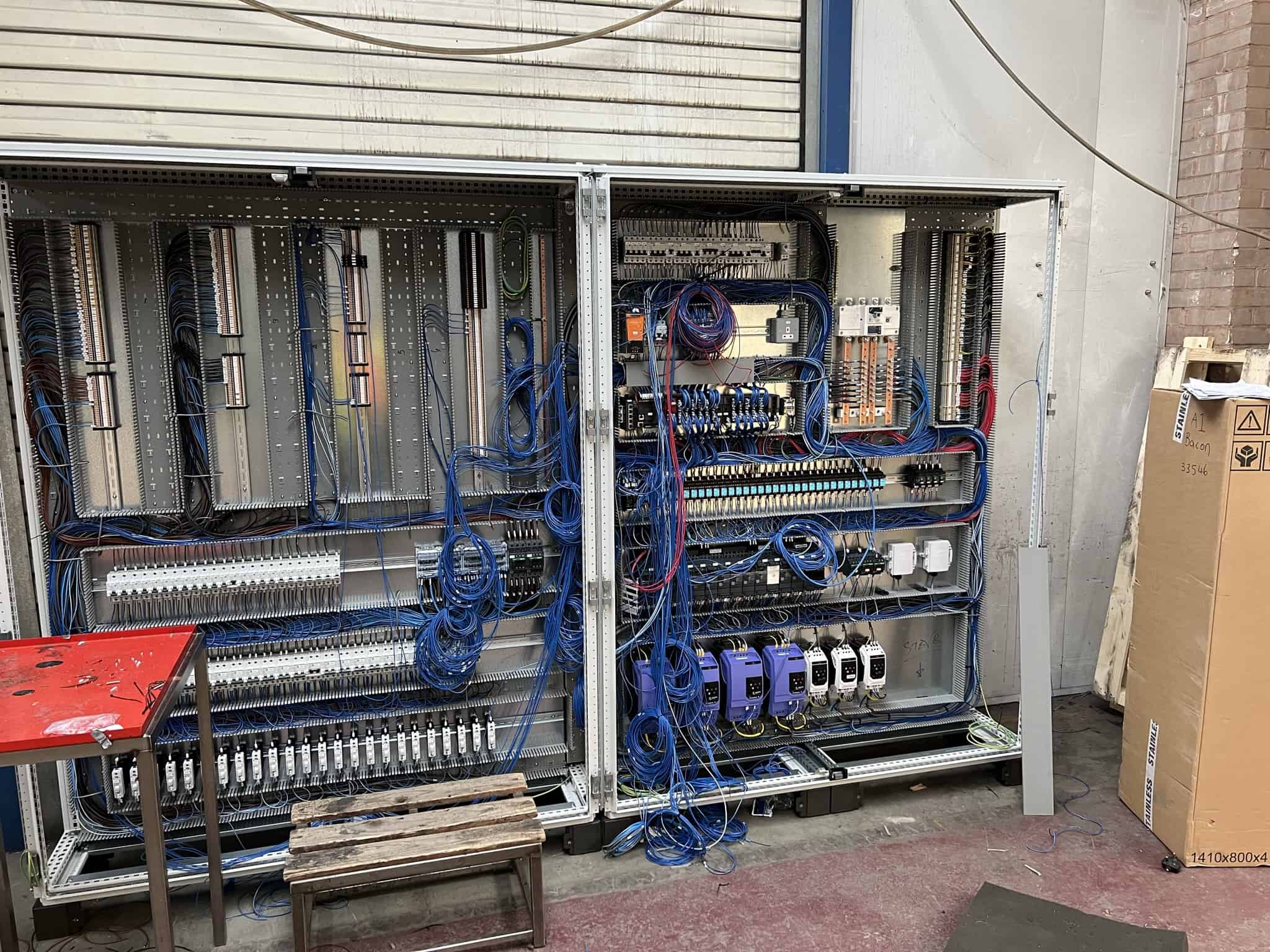

Automation control panels are used and act as the command center for the entire system. These control systems are supplied by our inhouse team, designed to coordinate conveyor operations, sensors, motors, and other components for smooth and reliable performance. All major PLC manufacturers equipment may be incorporated. This includes the following:

- Siemens

- Allan Bradley

- Telemechanique

- Mitsubishi

HMI’s are extensively used for system operation, data entry and recipe handling.

Robot Integration

With years of experience in conveyor automation, we understand how to adapt your conveyor system to work harmoniously with robotic technology. Whether you’re upgrading an existing line or setting up a new one, we’ll ensure your robots and conveyors operate as one cohesive, high-performing unit.

- Precise Timing: Our systems synchronise conveyor movement with the speed and actions of robots.

- Safe Integration: We ensure the layout and operation comply with safety standards.

Contact Us Today

To discuss your conveyor automation needs – contact us today on 01543 675800 or email us at info@unitech.uk.com. We’re here to help.