Pharmaceutical Conveyors

Unitech specialise in conveyor solutions designed to meet the demanding standards of the pharmaceutical industry. Our systems support safe, hygienic and efficient product movement throughout the entire manufacturing process.

We offer a wide range of conveyors suited to pharmaceutical operations. These can be fully bespoke and made to measure to your exact specifications.

Cable Conveyors

Cable conveyors are ideal for transporting products that require protection from contamination.

- Protects products from external contaminants

- Gentle transport for fragile goods such as tablets and capsules

- Reduces risk of cross contamination between production areas

Chain Indexing Conveyors

Chain indexing conveyors are used where controlled movement and precise positioning are essential. Products move in set steps, rather than continuously.

- Accurate positioning for bottle filling, labelling or inspection

- Suitable for timed operations such as blister packaging

- Supports consistency across production lines

Roller Conveyors

Roller conveyors are highly effective for moving packaged goods, cartons, and bulk materials throughout the facility. There are two types: gravity rollers and powered rollers.

- Reduces manual handling and supports operator safety

- Smooth flow of goods across longer distances

- Supports accumulation to regulate busy production periods

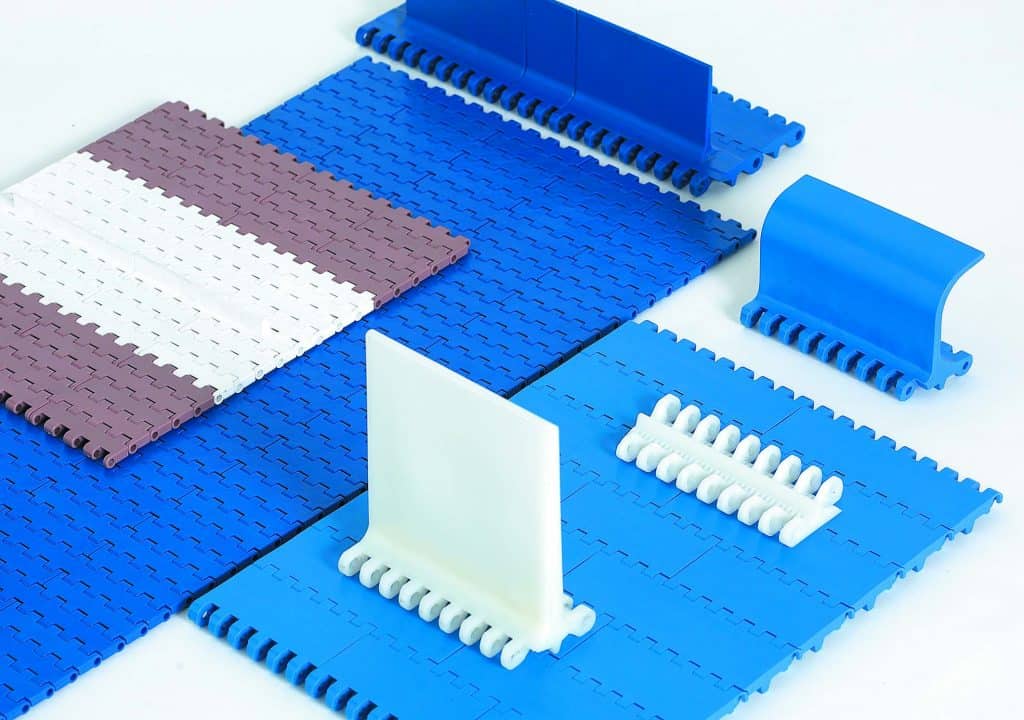

Modular Belt Conveyors

Modular belt conveyors use interlocking plastic belts that can be quickly cleaned or replaced if needed, without major downtime.

- Fast cleaning and easy maintenance

- Flexible layouts, including inclines, declines and curves

- Strong support for complex production floor designs

PU Belt Conveyors

Polyurethane belt conveyors provide a smooth, chemical resistant surface ideal for direct contact with pharmaceutical products.

- Safe transport of unpackaged products such as blister packs and tablets

- High resistance to moisture and cleaning agents

- Maintains hygiene during continuous operations

Spiral Conveyors

Spiral conveyors allow for vertical movement between production levels, saving valuable floor space.

- Moves products vertically without needing lifts

- Compact design to maximise floor space

- Smooth, continuous product flow between floors

Magnetic Conveyors

Magnetic conveyors are designed to move ferrous materials securely, even along vertical or inclined paths.

- Secure handling of items that contain metal or are held in place by magnetic strips

- Reduces risk of product loss during transport

- Maintains product positioning throughout movement

Trough Conveyors

Trough conveyors cradle products gently, making them suitable for bulk transport of irregularly shaped or loose materials.

- Stable movement of powders, granules, or tablets

- Reduces spillage during transport

- Ideal for transferring bulk materials between stages

Vibratory Conveyors

Vibratory conveyors use controlled vibrations to move products gently without mechanical stress.

- Gentle handling of small or fragile products such as loose pills

- Gentle use of vibrations (no belts or rollers), so products are less likely to chip, crack, or bounce off

- Reliable transfer of parts to capsule or filling lines

Every pharmaceutical production line has its own challenges. Whether you are handling fragile capsules, sterile vials, bulk powders or packaged goods, Unitech Conveyors can supply a system that matches your needs.

Our team works closely with clients from initial consultation through to installation and support, providing advice on the best conveyor systems to optimise product flow, maintain hygiene standards and support future growth.

Contact Us Today

Contact us today to get your pharmaceutical conveyor project started

- Full turnkey conveyor solutions

- Over 70 years of experience

- In-house design team

- Friendly and helpful customer service

☎ – 01543 675800