In this guide, we take a look at the types of conveyors used in warehouses, their benefits and how they can work for both large and smaller facilities.

Why Warehouses Use Conveyor Systems

As you’re probably very well aware, warehouses are busy environments! Staff move goods all day, often across large spaces. Without conveyors, this work can be slow and tiring.

There are several clear reasons why warehouses choose to install conveyors:

- Faster movement of goods.

- Fixed routes make it easier to sort and track packages.

- Products can be safely and efficiently moved from mezzanine floors via incline conveyors, or spiral conveyors.

- Products can be quickly and accurately sorted via barcodes, labels, weights etc.

- Reduced risk of product damage.

- Reduced lifting helps prevent back strain and common workplace injuries.

- Reduced forklift truck movements within the warehouse.

What Types of Conveyors are used in Warehouses?

There are several types of conveyors, each suited to different tasks. Warehouses often use more than one type, depending on the size of the building and the goods being moved.

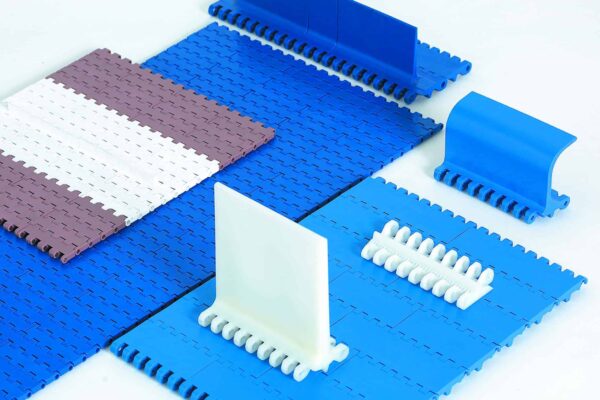

Belt conveyors

These are the most commonly used in warehouses. They use a moving belt to carry items from one point to another. Ideal for boxes, parcels, and packaged goods.

Roller conveyors

These use rows of rollers instead of a flat belt. Items are transported either by gravity or with a motor. Perfect for heavier loads, such as crates or pallets. They are simple in design and often cost less than belt systems.

Overhead conveyors

Overhead conveyors hang from the ceiling and carry items above the floor. This type of system is useful when space is limited.

Warehousing Conveyor Automation

Automation takes conveyor systems a step further. Instead of simply moving items from A to B, automated systems can sort, scan, and direct packages without manual input. Sensors, barcode scanners, and software work together to guide items along the correct routes.

In a large warehouse, automation can save hours of work each day. Packages are scanned as they move and sent to the correct packing or dispatch area. This reduces human error and speeds up order fulfilment.

Automation also improves visibility. Managers can track where goods are in real time. If a delay happens, it is easier to spot the problem and fix it quickly. Data from automated systems can also show patterns, such as peak times or slow points in the workflow.

Conveyors for Smaller Warehouses

We know that not every warehouse is a huge distribution centre. Smaller warehouses and stockrooms can also benefit from compact conveyor systems. The key is choosing the right scale and layout.

So for smaller operations, the goal is usually efficiency rather than full automation. Even a short conveyor line between your storage and packing area can save a lot of walking time each day. Over weeks and months, this adds up to noticeable gains in productivity.

Budget is usually another key factor for smaller warehouses. Simple roller conveyors or gravity systems often provide good value without high costs.

Ready to Improve Your Warehouse Flow?

If you are thinking about upgrading your warehouse or installing a new conveyor system, now is the time to act. Let us help design a solution that keeps your goods (and your business) moving forward.

Simply contact us today on 01543 675800 or drop us an email – info@unitech.uk.com